Buy welding extruder Leader-5

Dear customer,

we Express our gratitude to you for purchasing Our product manual welding extruder Leader-5. We have a powerful laboratory of 1000 m2 and a large production base, we produce various products! The main direction is manual welding extruders, our equipment is represented on the world market. There are copyright certificates and patents. Our equipment is used at many sites and we also work with our own equipment. Delivery throughout Russia and the CIS.

GENERAL INFORMATION

powerful manual welding extruder «LEADER-5». Brews a rod of circular cross section of 3-4 mm on both sides. Soft start. The extruder has protection against engine overheating during operation. Power cord 3 meters from the ground. The extruder comes in a good case of the production of ITTs-Extradermal.

The purpose of the product

Permanent connection of parts (sheets, pipes, profiles) made of thermoplastic polymer materials by feeding a homogenized mass of filler material into a heated bath formed by the edges of the parts to be connected.

Application

Production of pipelines, aeration systems, tanks, septic tanks, sheet and film structures for various purposes, elimination of defects in plastic products, etc.

Principle of operation

The filler material (rod) is inserted into the technological hole for the rod, from where it enters the grinding chamber through the stretching mechanism, then it is captured by the screw and enters the heating zone, passing through which it acquires a plastic state. As a heat carrier in the heating Chamber, hot air is used, supplied from the hair dryer through a pipeline. The screw rotation is driven by a low-speed mixer.

The homogenized mass of the filler material is fed into the welding zone through the hole of the welding nozzle. Heating of the connected parts in the welding zone is performed by hot air, which is supplied under pressure through the outlet of the heating chamber. On The Sleeve.

For convenience, the product is equipped with a handle. The parameters of the weld are determined by the parameters of the cross-section of the output hole of the replaceable welding nozzle.

Manual welding extruder Leader-5

ATTENTION! Preparation for operation:

before starting work, warm up the mechanism for 7-10 minutes at a temperature of 350-360 degrees.

ABSOLUTELY! warm up the nozzle well.

Set the heating and air supply device mode» warm-up » to a temperature of about 260 degrees. (operating temperature)

a temperature controller is installed On the hair dryer . We can see the temperature readings on the display.

Note:

For welding plastics, we set the temperature on the hair dryer a little more. (When the hot air comes out of the extruder nozzle, it connects with the surrounding air, and a small error is obtained on the nozzle. Weather conditions must be taken into account.

3. Insert the rod into the process hole.

Click on the drive button. ON FULL!!! start welding at full speed. (The drive must cool itself!)

4. the seam forming Nozzle must rotate 360 degrees along the thread. (it is not necessary to delay it).

:

Make a test seam. The extrusion should not flow(this is overheating). Move the temperature controller to the position where the temperature will be 260 degrees.

During operation, visually monitor the quality of the weld. The extrusion must be elastic.

If it is necessary to temporarily stop working, the heating and air supply device should be switched to (0) mode. When resuming operation, set the operating mode again.

At the end of the work, it is necessary to cut the rod and expel the remains of the molten mass from the rod capture chamber to the heating chamber.

Security measures:

The product meets all requirements that ensure the safety of life and health of the consumer, as well as environmental protection.

Keep in mind that the temperature of the extruded mass of the filler material, as well as the temperature on the surface of the welding nozzle and the heating chamber during operation is at least 150 degrees Celsius.

It is forbidden: to Work without grounding, to work in wet weather, to work with faulty wiring, to use the extruder for other purposes, to work without a certificate or other authorization document for training with a manual welding extruder, to leave it unattended,to work without preheating the extruder(there is no protection against «cold start»), to make any changes to the design. It is forbidden to work near explosive liquids, compounds, objects, unstable position of the operator and the structure being welded. It is forbidden to transfer the extruder to an untrained and untrained person who does not have a permit.. It is forbidden to work in the dark, or in poor light. It is forbidden to work with materials that emit toxic substances.

Guarantee of long-term operation of the equipment and the quality of the weld.

Recommendations

Welding extruder

Use only high-quality welding material to work with a manual welding extruder, thus you will get a high-quality strong and sealed seam.

Read all the sections carefully and follow the requirements set out in them.

Before starting work, check the operation of the extruder.

Install the required attachment and make sure that it is securely and correctly attached;

Check the operation of the extruder by turning it on for 10 minutes.

You can get started.

The price of the extruder (Leader-5) is 59,000 rubles.

The set includes 2 shoes.

The price of an additional nozzle (metal) for Your tasks is 800 rubles.

The price of an additional nozzle (fluoroplast) is 2500 rubles.

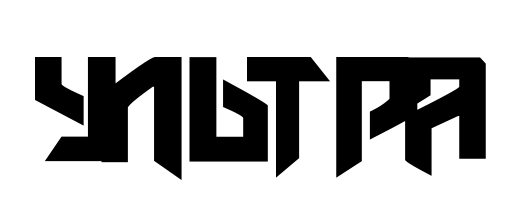

Products Manual welding extruder Leader-5 No. 019628630-061I.

Warranty repair of the mechanical part of the extruder is 1 (one) year.

Warranty service does not apply to the hair dryer and mixer. The hair dryer can be installed by any manufacturer and any price category. The seat is 40mm. The power of the hair dryer is not less than 2000 watts.

Technical specifications-page 3

Manufacturer of products Engineering and technical center (SP Matveev S. V.)

date of manufacture 28.010.2019

Copyright certificate

Extruders

To purchase a manual welding extruder

Our engineering and technical center produces manual welding extruders for welding plastics.

Manual welding extruders from the ITC-Extruder plant, reliable devices of Russian production.

Form the configuration of the seam from the molten mass (extrusion). We have about 20 attachments.

Manufacturer of manual extruders

Engineering and technical center «Extrudermash» is engaged in welding manual extruders razrabotkoi (Leader-1, Leader-1M, Leader-2, Leader-3, Leader-4, Leader-5, Leader-6, RS-1, RS-1M, RS-3, RS-5, RS-6, Ural-1, Ural-2, Ural-Ural I. 3-3P) muvyr welding of plastics.

ITTs-Extradermal is located in Schelkovo, Moscow region

Please fill out the feedback form and we will contact you or just call!

we Carry out orders for any individual development, please contact us we will design any individual project.

[/qode_banner]

Any questions?

You can find out all the details from the head of the company Sergey Matveev by calling:

+7 (499) 955-45-92 or +7 (985) 000-64-65